Competencies

CEN PCBA fulfills your electronic manufacturing needs with industry-leading engineering capabilities, material sourcing, manufacturing services, quality assurance and reliability testing.

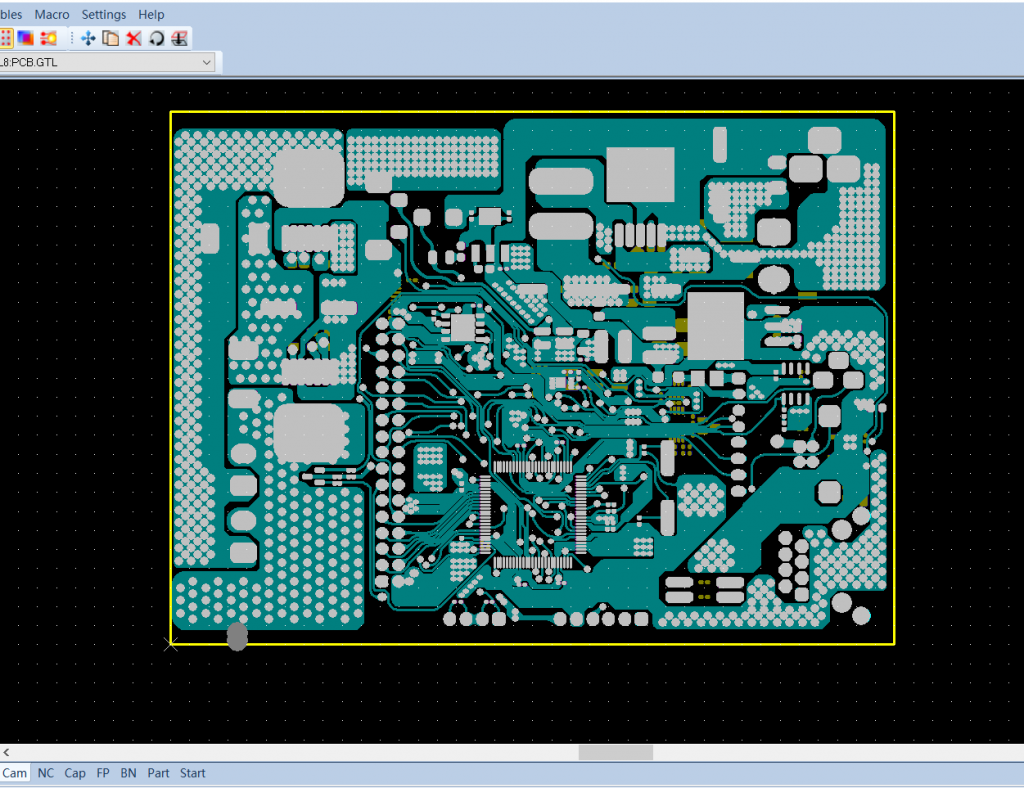

Engineering

Over the years, CEN’s engineering design teams have developed and introduced many products into manufacturing. Seveco’s team is able to assist its clients at all stages of their product development from initial concept through manufacturing, we are capable of:

- PCB layout & electrical design

- Test Lab report & agency approval: UL, CE, IC, FCC, C-Tick, CSA, etc.

- Mechanical design, injection tool design & mold flow analysis

- Manufacturing process development

- Prototype assembly

- DFM/DFT reviews

- Test development, design test software & fixtures

Components Procurement

CEN employs an expert material procurement planning team. Utilizing a client’s Bill of Materials (BOM), Approved Manufacturers List (AML) and Enterprise Resource Planning (ERP) software, the team will manage material procurement plan to achieve customer’s mass production & shipment schedule.

Material procurement is made with strict adherence to the client’s AML, alternate components are always considered for cost & lead time efficiency, they are submitted to the client for approval and addition to their AML list

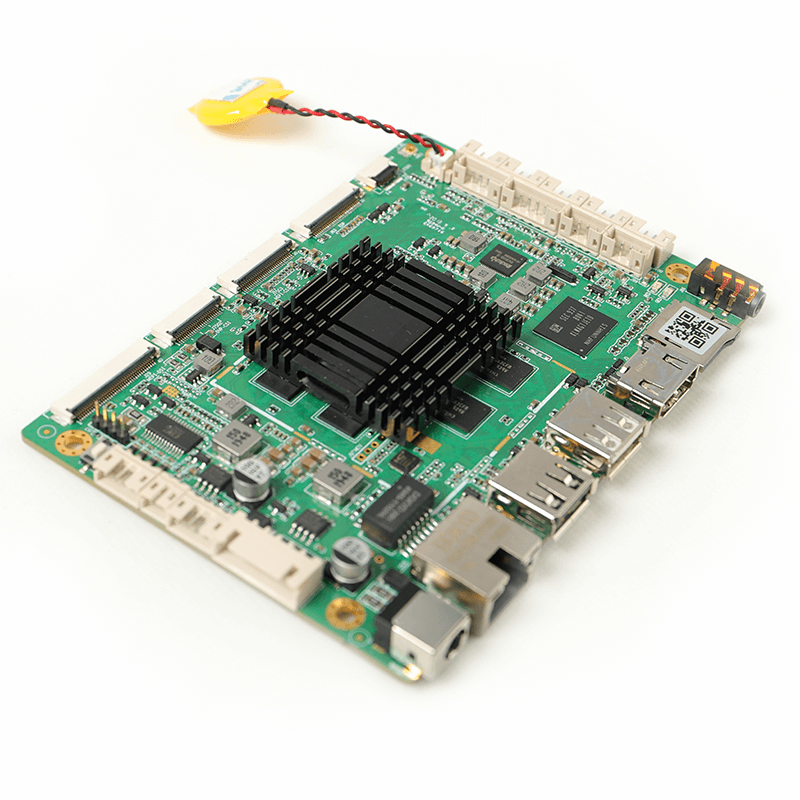

PCB Assembly

CEN is primarily a turn-key box build electronics manufacturer. CEN is capable of taking a client’s PCB, PCBA, FPCB, Ragid Flex Assembly into a high quality product and shipped to any destination in the world. Key highlights of CEN’s manufacturing capabilities include:

- 10 SMT lines, SMT fine pitch down to 01005

- RoHS & REACH compliance

- BGA, pitch down to 0.3mm & X-ray inspection

- Computer Bar-code based component Pick & place system

- Automatic Optical Inspection (AOI) on all SMT lines

- Automatic Conformal Coating & Vacuum potting

- Ultrasonic Welding

- Flexible setup Line & Cell manufacturing

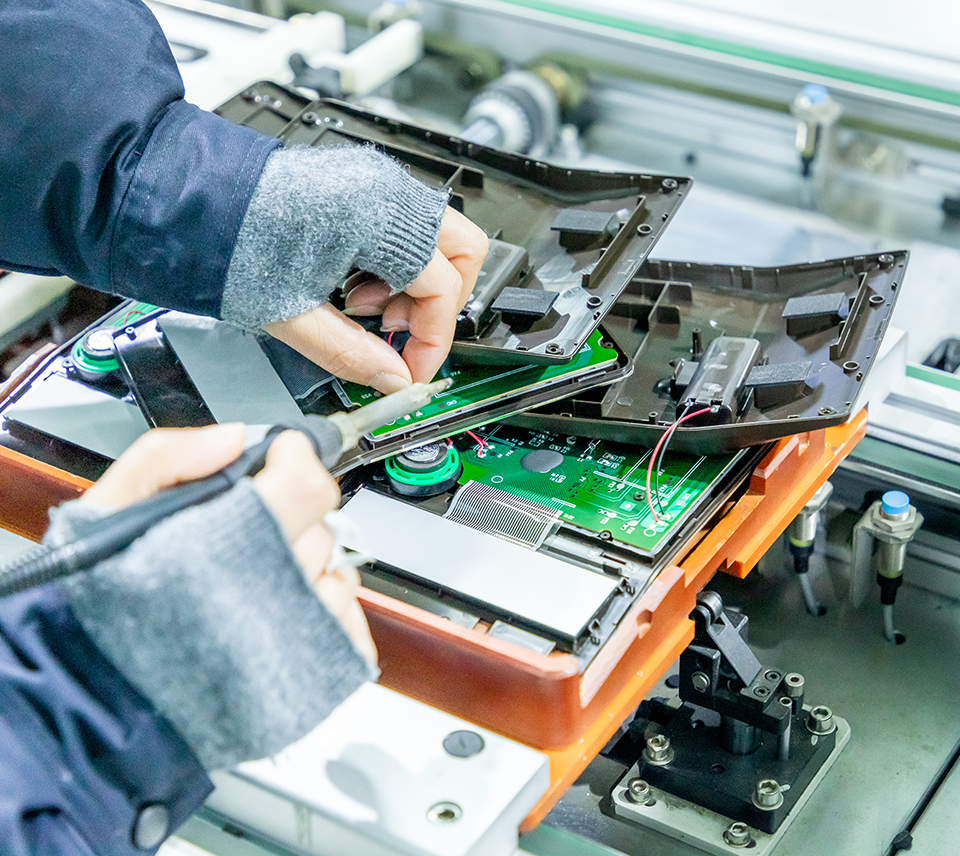

Box Build

“Box build,” also known as systems integration, is a complete assemble process of finished product that has exhaustive research and development. Following is a list of what Mars can do for box build assembly service:

- system level assemb

- product assembly

- sub-level product assembly

- packaging

- labeling

- testing\software installation

- product configuration

- warehousing

- order fulfillment

- after-market service

- repairing

Test Development

CEN develops and manages a wide range of production test processes, from passive In-Circuit PCBA testing, through fully-automated final test stations. CEN works closely with its clients to ensure all test and verification is performed in compliance with established product specifications and requirements.

- Passive In-circuit testing

- Fully automated, manual functional, and final acceptance testing

- On-line & off-line function testing

- Audio frequency testing

- RF Radio product testing

- Faraday cage test chambers

- Client test process reporting and statistics

Supply Chain Management

CEN can source all the parts and components you need for your product through our network of reliable and trusted distribution partners. The combination of our expertise and our long-term relationships with our distribution partners allows us to source component parts for the average bill of materials (BOM) in the shortest time. Our supply chain management ensures efficiency, lowers costs, raises profits, boosts collaborative work, and more. We work with our customers right from the quoting stage to devise an initial sourcing strategy based on specific production requirements. From there, we continually strive to identify cost reduction opportunities, to provide our customers the lowest total cost of ownership.

WE ARE HERE FOR YOU