Introduction

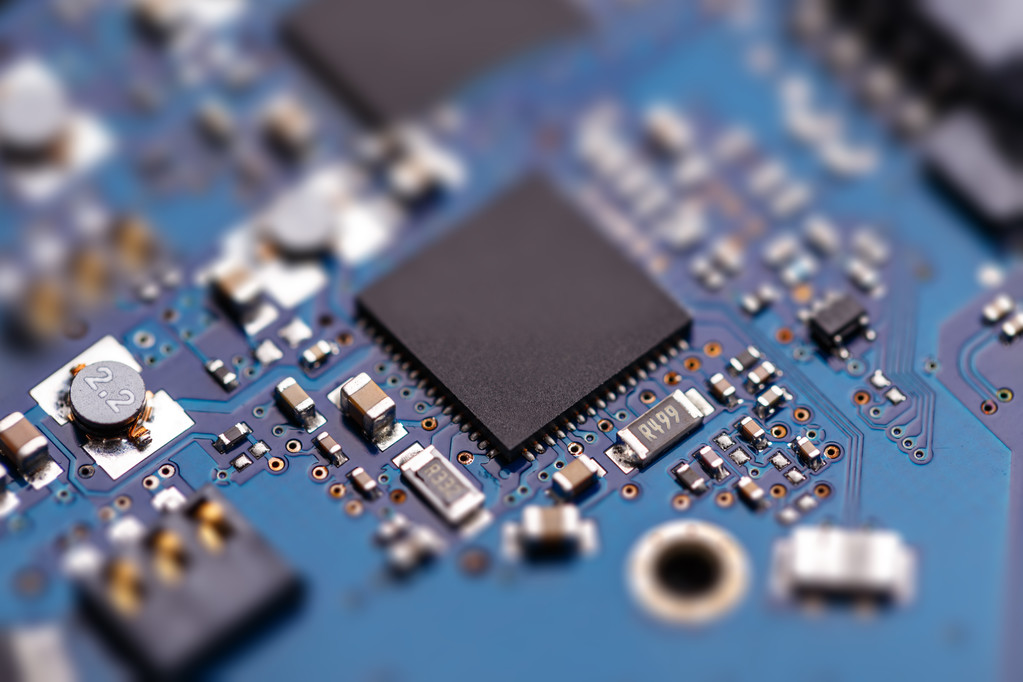

The Internet of Things (IoT) market is a dynamic and rapidly evolving landscape, characterized by continual advancements and innovations. As the demand for connected devices continues to soar, PCB assembly plays a pivotal role in bringing these IoT solutions to life. In this comprehensive guide, we’ll delve into the intricacies of PCB assembly in the IoT sector, exploring key components, technologies, and manufacturing considerations.

Understanding PCB Assembly in the IoT Sector:

The IoT sector encompasses a vast array of applications, from smart factories and industrial automation to remote monitoring and predictive maintenance. PCB assembly in the IoT sector involves the manufacturing and integration of printed circuit boards tailored specifically for IoT devices used in industrial settings. These devices are designed to collect, transmit, and analyze data, enabling organizations to optimize operations, enhance efficiency, and drive innovation.

Key Aspects of PCB Assembly in IoT:

Miniaturization

One of the defining characteristics of IoT devices is their compact form factor and lightweight design. PCB assembly for IoT demands advanced miniaturization techniques, including surface mount technology (SMT), small-sized components, and multi-layer PCBs. These innovations enable the creation of smaller, more lightweight IoT devices that can seamlessly integrate into industrial environments.

Wireless Connectivity

Wireless connectivity is essential for IoT devices to communicate with other devices, sensors, and cloud platforms. PCB assemblies in the IIoT sector incorporate a range of wireless communication modules, including Wi-Fi, Bluetooth, Zigbee, cellular (2G, 3G, 4G, or 5G), and low-power wide-area network (LPWAN) technologies like LoRaWAN and NB-IoT. These modules enable reliable and secure wireless communication, facilitating real-time data exchange and remote monitoring.

Sensor Integration:

Sensors play a crucial role in IoT applications, enabling devices to collect data from the physical environment. PCB assemblies in the IoT sector integrate sensor interfaces and circuits to connect and interface with various sensors, including temperature sensors, humidity sensors, motion sensors, and light sensors. These sensors provide valuable insights into industrial processes, equipment performance, and environmental conditions.

Power Efficiency

Power efficiency is paramount in IoT applications, where devices are often battery-powered or operate on low-power sources. PCB assemblies in the IoT sector incorporate power management techniques such as power regulators, energy harvesting components, and low-power microcontrollers. These components optimize power consumption, extend battery life, and ensure reliable operation in industrial environments.

Data Processing and Control

IoT devices require robust processing capabilities to analyze and process the vast amounts of data generated by sensors and devices. PCB assemblies in the IoT sector include microcontrollers or system-on-chip (SoC) components with integrated processing power, memory, and interfaces for data processing and control functions. These components enable real-time data analysis, decision-making, and control within industrial settings.

Security:

Security is a critical consideration in IoT applications to protect sensitive data, prevent unauthorized access, and ensure the integrity of industrial processes. PCB assemblies in the IoT sector may incorporate security features such as secure elements, encryption algorithms, and tamper detection circuits. These features enhance the security of IoT devices and safeguard against cybersecurity threats.

Cloud Connectivity:

Cloud connectivity is essential for IoT devices to transmit data to cloud platforms for storage, analysis, and visualization. PCB assemblies in the IoT sector include cloud connectivity options such as MQTT (Message Queuing Telemetry Transport) or other protocols, enabling seamless data transmission to cloud services. These connections facilitate remote monitoring, predictive maintenance, and data-driven insights for industrial operations.

Integration with Edge Computing:

Edge computing plays a vital role in IoT applications, enabling real-time data processing and analysis at the device level. PCB assemblies in the IoT sector may incorporate edge computing capabilities through the integration of processing units and algorithms. These components enable devices to perform local data processing, reducing latency, and improving response times in industrial environments.

Essential Components Used in IoT PCB Assemblies:

PCB assemblies for IoT applications incorporate a diverse range of components to enable functionality, connectivity, and intelligence. Here are some essential components commonly used in IoT PCB assemblies:

Microcontrollers:

Microcontrollers serve as the brain of IoT devices, providing processing power and control capabilities. They handle data processing, device management, and communication protocols, enabling seamless operation in industrial environments.

Wireless Communication Modules:

Wireless communication modules facilitate wireless connectivity in IoT devices, enabling communication with other devices, sensors, and networks. Modules such as Wi-Fi, Bluetooth, Zigbee, and cellular enable reliable data transmission and communication in industrial settings.

Sensors:

Sensors are integral to IoT applications, enabling devices to collect data from the physical environment. Temperature sensors, humidity sensors, motion sensors, and other sensors provide valuable insights into industrial processes and environmental conditions.

Power Management Components:

Power management components optimize power usage and prolong battery life in IoT devices. Battery charging circuits, voltage regulators, and energy harvesting modules ensure efficient power distribution and consumption in industrial environments.

Memory Devices:

Memory devices store data, program code, and firmware updates in IoT devices. EEPROM, Flash memory, and SD cards provide reliable storage solutions for industrial applications.

Interface Components:

Interface components enable communication between IoT devices and external peripherals. Serial communication modules, USB interfaces, Ethernet modules, and display interfaces facilitate data exchange and interaction in industrial environments.

Analog-to-Digital Converters (ADC):

ADCs convert analog signals from sensors into digital signals for processing by microcontrollers. They play a vital role in capturing and interpreting real-world data in IIoT applications.

Security Components:

Security components enhance the security of IoT devices, protecting against unauthorized access and cybersecurity threats. Encryption modules, secure elements, and authentication chips safeguard sensitive data and ensure the integrity of industrial processes.

Passive Components:

Passive components such as resistors, capacitors, inductors, and crystals are fundamental for circuit operation and signal conditioning in IoT PCB assemblies. They control current, voltage, and timing, ensuring reliable performance in industrial environments.

Connectors:

Connectors facilitate physical connections between PCBs and external devices or peripherals in IoT applications. Pin headers, USB connectors, RJ45 Ethernet connectors, and wire-to-board connectors enable seamless integration and communication in industrial environments.

PCB assembly plays a critical role in the development and deployment of IoT solutions in industrial settings. By leveraging advanced technologies, components, and manufacturing processes, organizations can create smart and connected devices that optimize operations, enhance efficiency, and drive innovation in the IoT sector. With a comprehensive understanding of PCB assembly in IIoT and a focus on quality, reliability, and security, companies can unlock the full potential of IoT technology and accelerate digital transformation in industrial environments.

CEN offers comprehensive PCB assembly services for IoT applications, with a focus on quality, reliability, and customer satisfaction. Contact us today to learn more about our capabilities and how we can support your IoT project requirements.

Pingback: The Rising Demand for PCB Camera Assembly in the Era of IoT - Contract Manufacturing